Hybrid injection molding machines have been on the market for a couple of decades now, and have proven themselves to be the standard choice in many facilities.

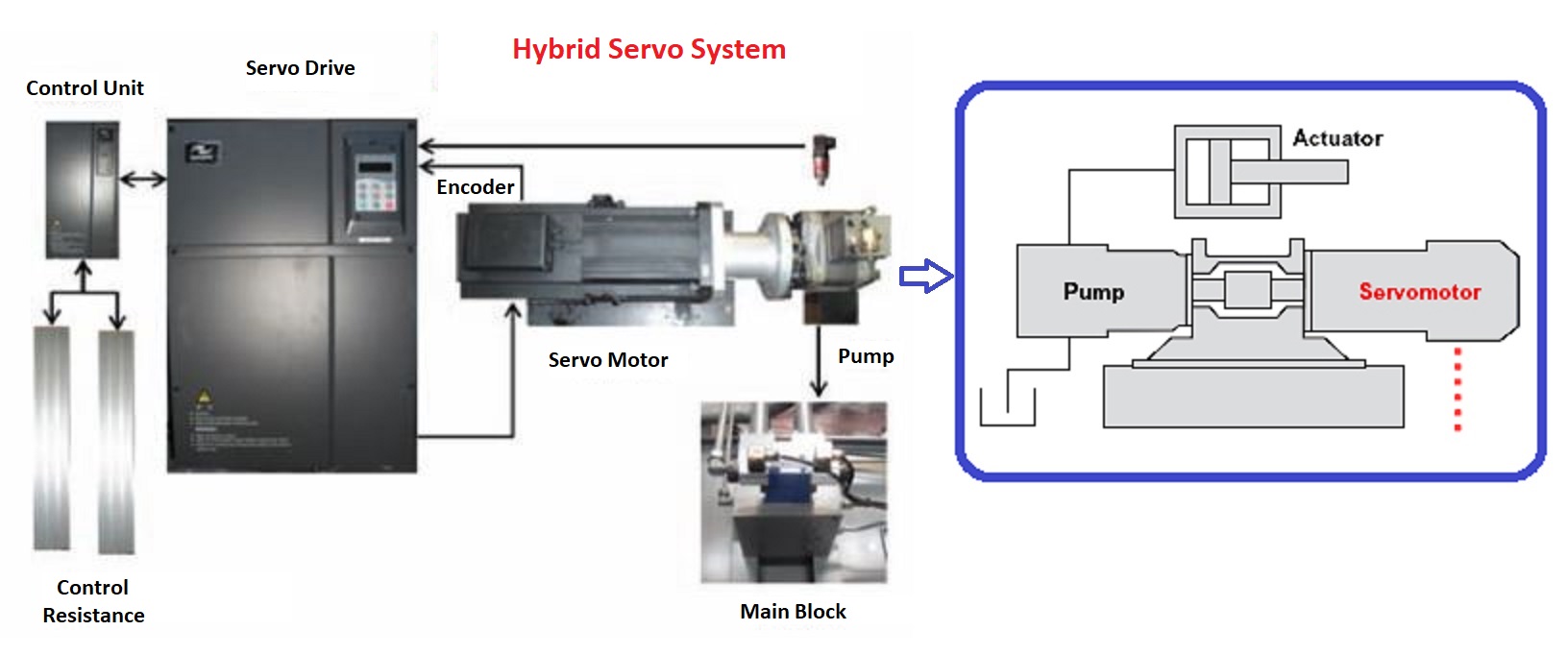

Hybrid injection molding machines are different compared to standard hydraulic injection molding machines in that they use a servo motor coupled to a hydraulic pump to circulate the oil used to provide the hydraulic pressure which actuates the components of the machine. The use of a servo pump allows for continuous adjustments to the actual power requirements, low emissions, less noise, and energy savings.

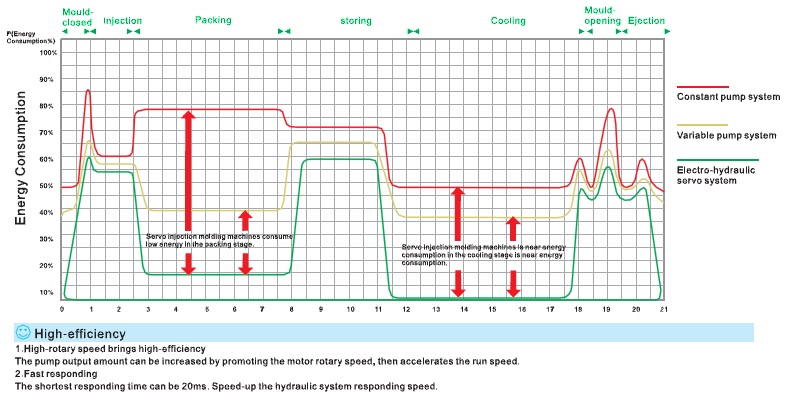

1. Energy Savings.

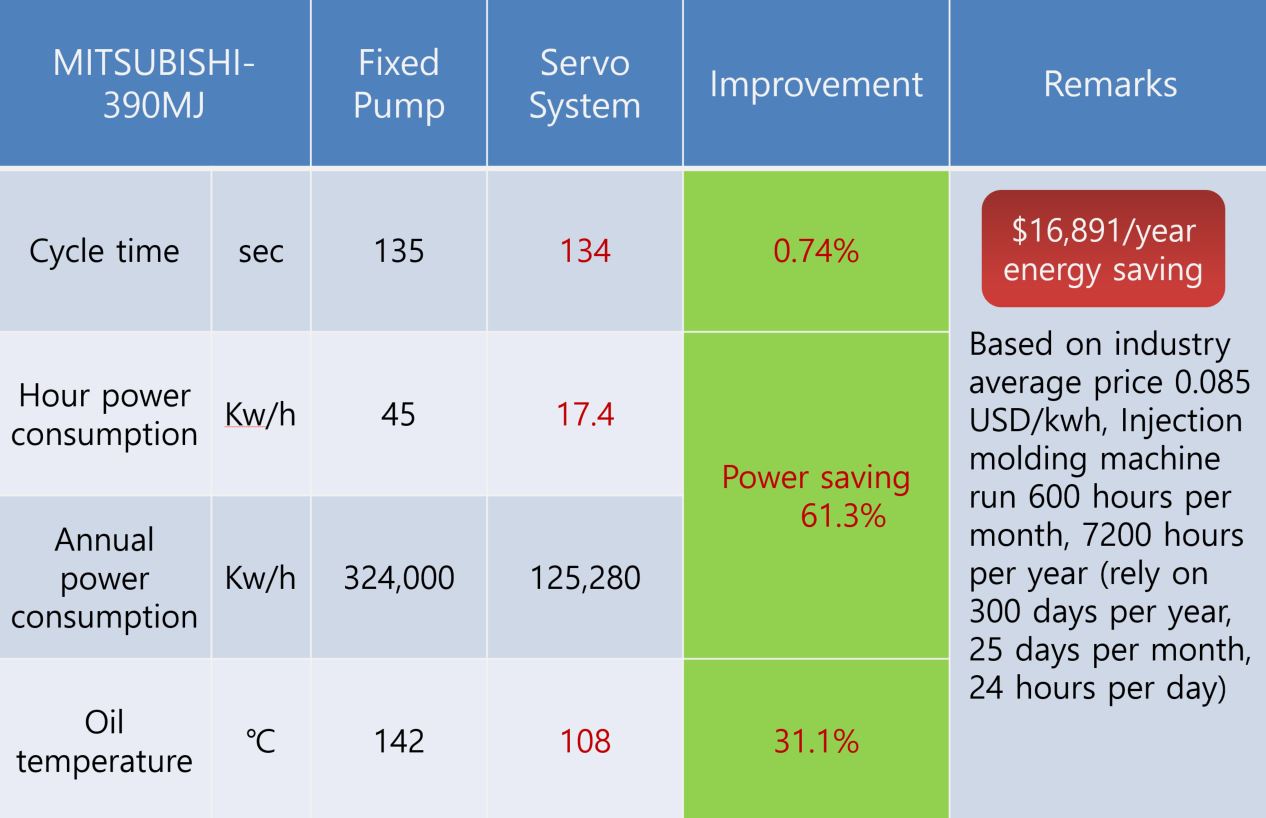

Compared to standard hydraulic machines, hybrid injection molding machines typically provide 40% to 60% in energy savings. This is because the servo pump only runs when hydraulic pressure is needed, where as a standard hydraulic machine runs the pump continuously. Because there is no need for movement during the cooling stage of the process, the longer the cooling time, the more energy savings you will see.

Hybrid machines that utilize toggle clamping mechanisms are more energy efficient than the direct ram style clamping units that many manufacturers use. Toggle mechanisms are more energy efficient in creating the clamping tonnage, and locking the mold halves together to maintain pressure.

2. Longer Hydraulic Oil and Machine Life.

Hybrid machines also run the hydraulic oil at a lower temperature because there is less circulation required. This leads to an extended lifespan of the oil, servo pump, and other mechanical components involved. Less maintenance means less downtime and more production with the hybrid injection molding machines.

3. Less Demand for Process Cooling Equipment.

When hydraulic oil runs at a lower temperature, it requires less cooling from your chiller or cooling tower. Today most injection molding machines come equipped with a water saver valve that adjusts the amount of water that flows through the heat exchanger to provide just the right amount of cooling so that you are not wasting money on excessive cooling. There are machines without a water saver valve so make sure your machine manufacturer adds this feature. Using less water from your tower or chiller reduces the heat load on your water system which will end up saving you money in the long run.

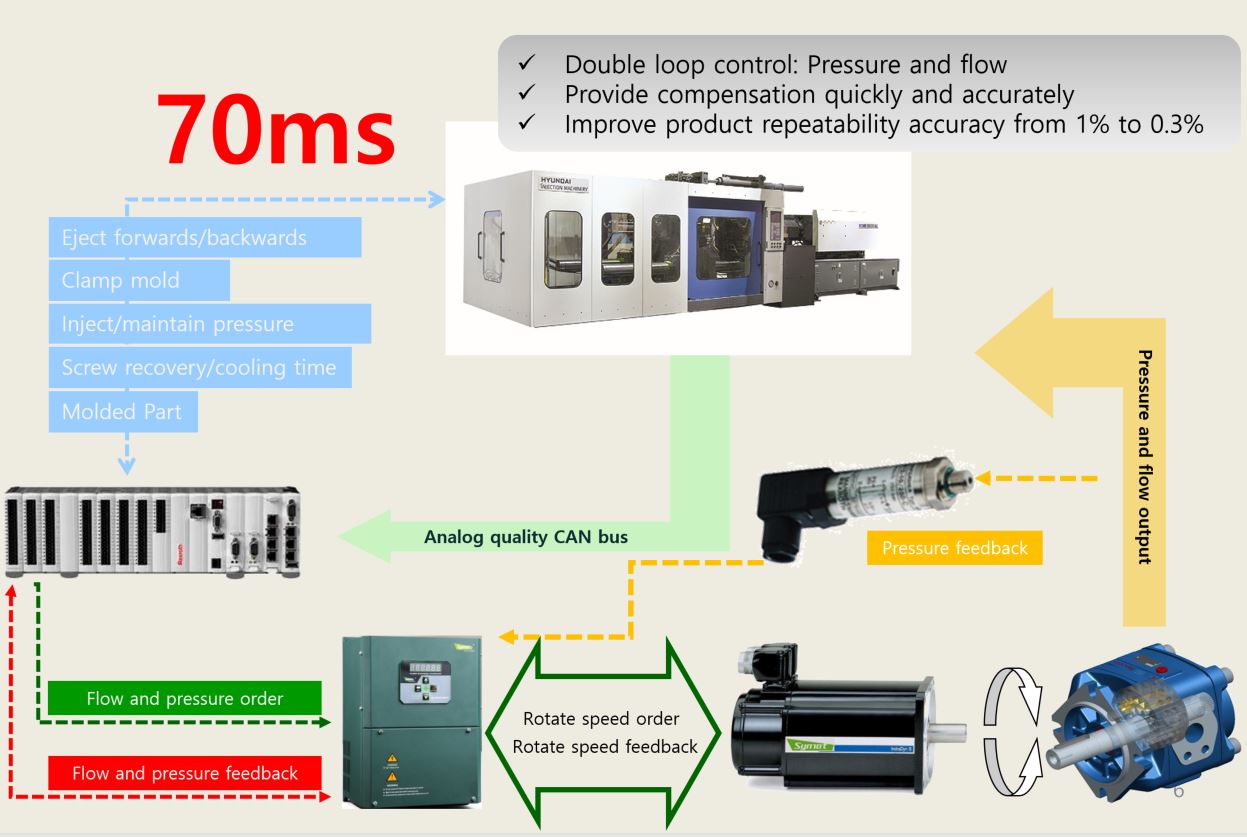

4. Faster Response and Closed Loop Process.

Servo motors have a faster response time than standard hydraulic pumps, which leads to faster cycles and decreased cycle times. They also offer more precise controls and a more consistent process due to the encoders that track each turn to the exact rotation position. This means higher quality parts and less scrap..

5. Faster ROI.

Although hybrid injection molding machines are slightly more expensive than standard hydraulic molding machines, all of the above benefits provide a very fast return on investment. Hybrid machines are also typically faster than standard hydraulic machines, so you will be able to make more parts in the same amount of time.

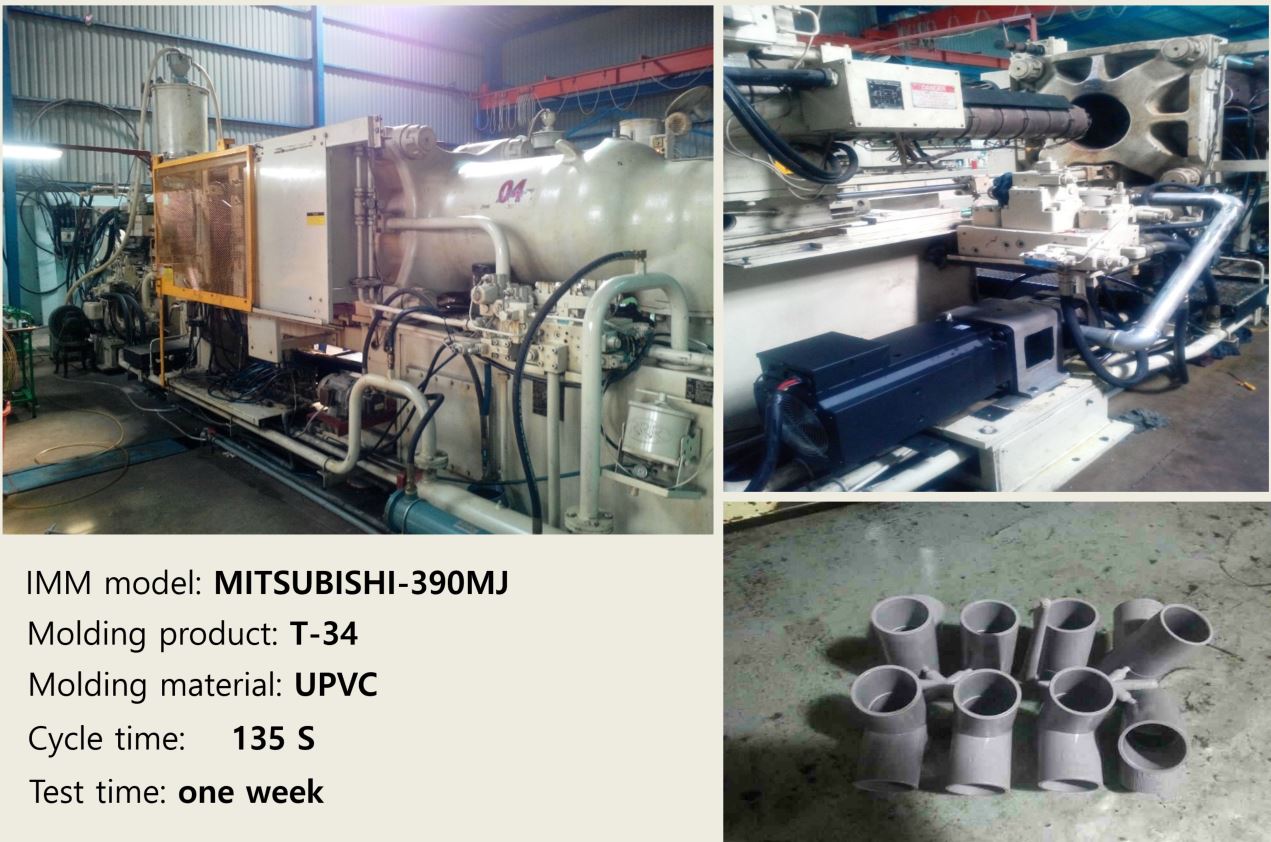

The case study below showcases an old Mitsubishi hydraulic injection molding machine that was retrofitted with a hybrid servo system.

Conclusion

Many of our customers have switched over to hybrid injection molding machines, or replaced their old standard hydraulic machines based on the benefits we talked about above, and all of our customers have noticed significant energy savings and increased production efficiencies. Hirate America is partnered with Hyundai Injection Molding Machines and LS Mtron Injection Molding Machines who manufactures hybrid injection molding machines in South Korea ranging from 80 to 6,000+ tons.

If you have a project that you would like to discuss, feel free to contact us below to schedule a free consultation.