Plastic processing has seen many changes over the years. We have seen significant advancements in process throughput and increased quality control as well as automation and controls. But one thing has remained surprisingly the same—the cooling systems. What most people do not realize is there are new technologies today that can reduce their industrial cooling system operating costs by over 40%.

Often overlooked or considered not as important as other parts of a plastic processing plant, process water cooling systems are gaining more attention as energy costs and concerns over water use continue to increase. There have been a number of advances in technology that provide increased efficiency to reduce production costs as well as global demand for power and fresh water.

Who doesn’t want to save a buck or two, every dollar savings counts when looking at overall operational costs annually.

1. Cut water use by 90% with Adiabatic Fluid Coolers.

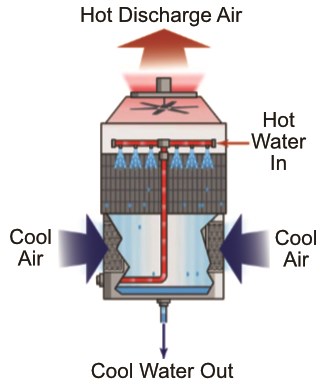

Most plastic processing facilities have a cooling tower to provide cooling to hydraulics, chiller condensers, and other process equipment. A cooling tower has a fan and evaporates water to produce 85°F process water. While effective at providing cooling, it uses a lot of water and requires water treatment to control biological growth. Cooling towers also expose the process water to the atmosphere and then require constant filtering.

With limited resources and a heightened awareness of the need to reduce energy and water consumption, the use of fluid coolers has become a popular alternative to conventional evaporative cooling towers.

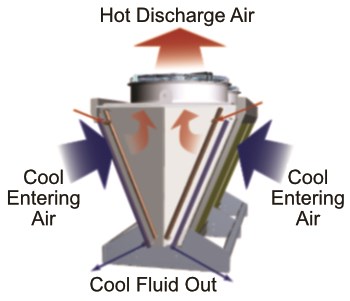

Similarly, a fluid cooler uses ambient air to cool the process water. However, this is done through a cooling coil and without exposing process water to the atmosphere. This method is effective but limited by the temperature of the ambient air. In most cases, the practical limit is a process of water temperature leaving the dry fluid cooler about 10°F warmer than the entering air temperature.

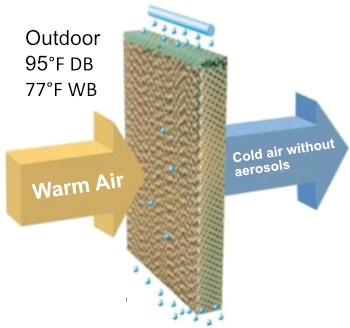

To expand the usefulness of fluid coolers as a replacement for evaporative cooling towers, manufacturers have added evaporative pads to their fluid coolers to pre-cool the warm summertime air through a process called adiabatic cooling. Adiabatic cooling occurs by evaporating water into the dry air entering the fluid cooler. As the air absorbs water, it is cooled and the cooler air is able to provide a consistent and stable output, leaving water temperature of 85°F to process.

Although this technology uses some water, the system is extremely water-efficient and only needed during peak summertime conditions. The result is as much as a 90% reduction in water use versus a conventional evaporative cooling tower. In addition, the water is fully evaporated and not recirculated, as is the case with a conventional cooling tower, so there is no need for water treatment. More on Adiabatic Fluid Coolers.

2. Reduce energy consumption up to 34% with variable-speed chiller compressors.

When plastics processes require water cooler than 85°F , a chiller is used. A chiller uses refrigerant, compressor and evaporator to remove heat from the process water and cool the process fluid to 50°F or so.

, a chiller is used. A chiller uses refrigerant, compressor and evaporator to remove heat from the process water and cool the process fluid to 50°F or so.

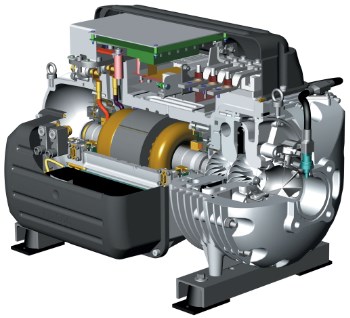

Compressors and the use of refrigerant have been around since the 19th century, and many different types of compressors are used, but until recently they all operated at one fixed speed

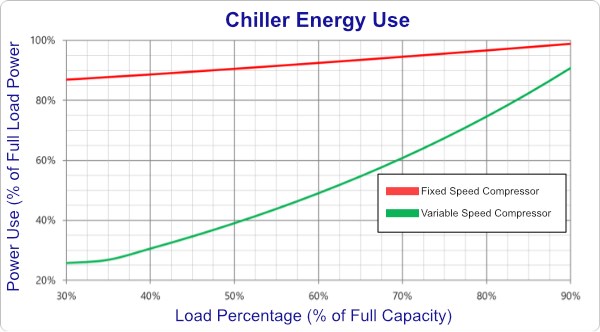

. A relatively new technology is variable-speed compressors. With this technology, energy use is reduced by slowing the speed of the compressor to just what is needed for the conditions.

When the compressor slows down, there is a reduction of cooling capacity. Most chiller system designs use the maximum possible heat load at 100% production capa

city of the process equipment to ensure there is always enough cooling capacity. In most cases, the production equipment is operating at much less than maximum capacity, so the chiller is ‘over-sized.’ A variable speed compressor is a great way to save this excess energy.

Power use is a “square relationship,” meaning that as the compressor speed changes, the power use changes as a square of the speed change. For instance, if a compressor operates at 80% of its maximum speed, it will use 64% of its full-speed power.

This technology is available in a wide-range of compressor sizes. In addition, the initial equipment cost premium for this technology, depending on the hours of operating and load profile, can pay for itself in 12 to 18 months. More on portable chillers and central chillers.

3. Dramatically cut chiller energy costs with free-cooling systems.

Considering the ever-increasing need for more efficient systems, the newest trend in central chiller system design is to combine the benefits of a variable-speed compressor with that of an adiabatic fluid cooler.

These hybrid systems use an adiabatic fluid cooler to cool the condenser of the chiller during the summertime, but when the outside ambient temperature is cool enough, the adiabatic fluid cooler directly cools the process water, which means the chiller turns off completely. This saves 100% of the electrical cost of operating the chiller, which is the most significant power consumption of any process cooling system.

The number of hours of free-cooling increases when the process fluid temperature is warmer. In many extrusion applications, the chilled water set point temperature is such that the chiller may only need to run 50% of the year.

Who doesn’t want to save a buck or two, every dollar savings counts when looking at overall operational costs annually.

Thermal Care continuously improves and innovates their products to be the best process cooling equipment systems in the industry.

If you have any questions regarding top entry robots, please contact any of the Hirate America team members to provide an automation solution tailored to your requirements.

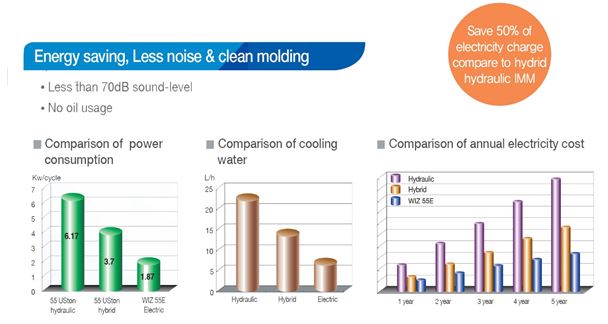

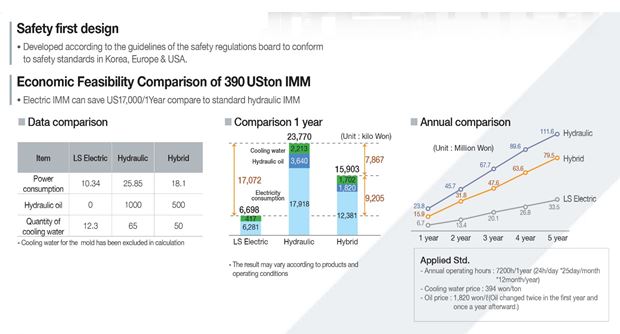

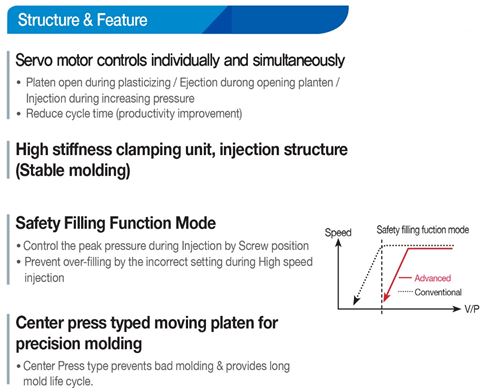

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.